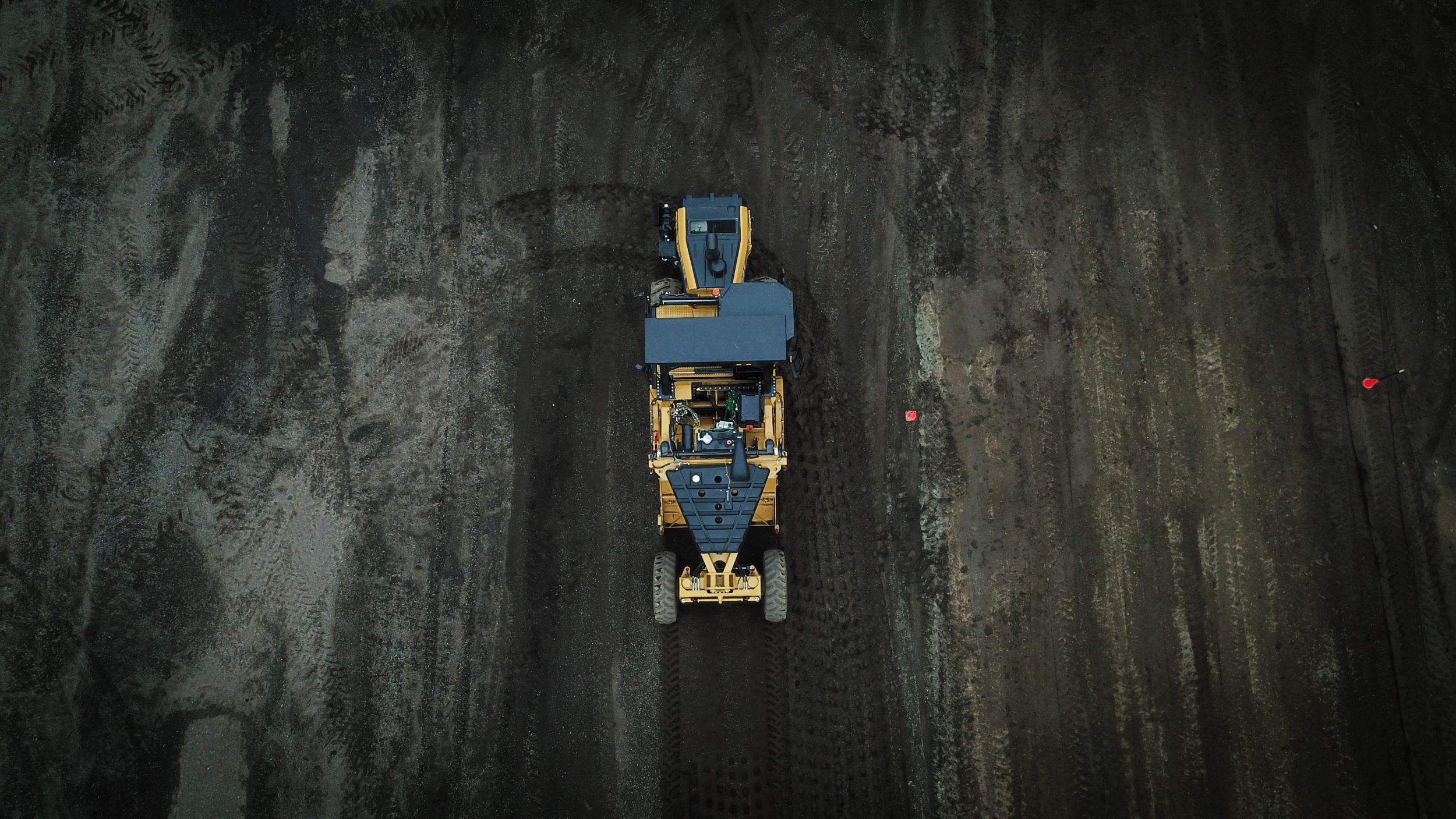

Technicial Specifications

| Maximum Operating Weight | 25960 kg |

| Cutting/Mixing Width | 2438 mm |

| Maximum Cutting/Mixing Depth | 508 mm |

| Operating Speed | 4.8 km/h |

| Maximum Travel Speed | 11 km/h |

| Rotor Options | Universal, Combination, Spade |

| Rotor Speed - First (at 2100 Engine rpm) | 108 r/min |

| Rotor Speed - Second (at 2100 Engine rpm) | 134 r/min |

| Rotor Speed - Third (at 2100 Engine rpm) | 159 r/min |

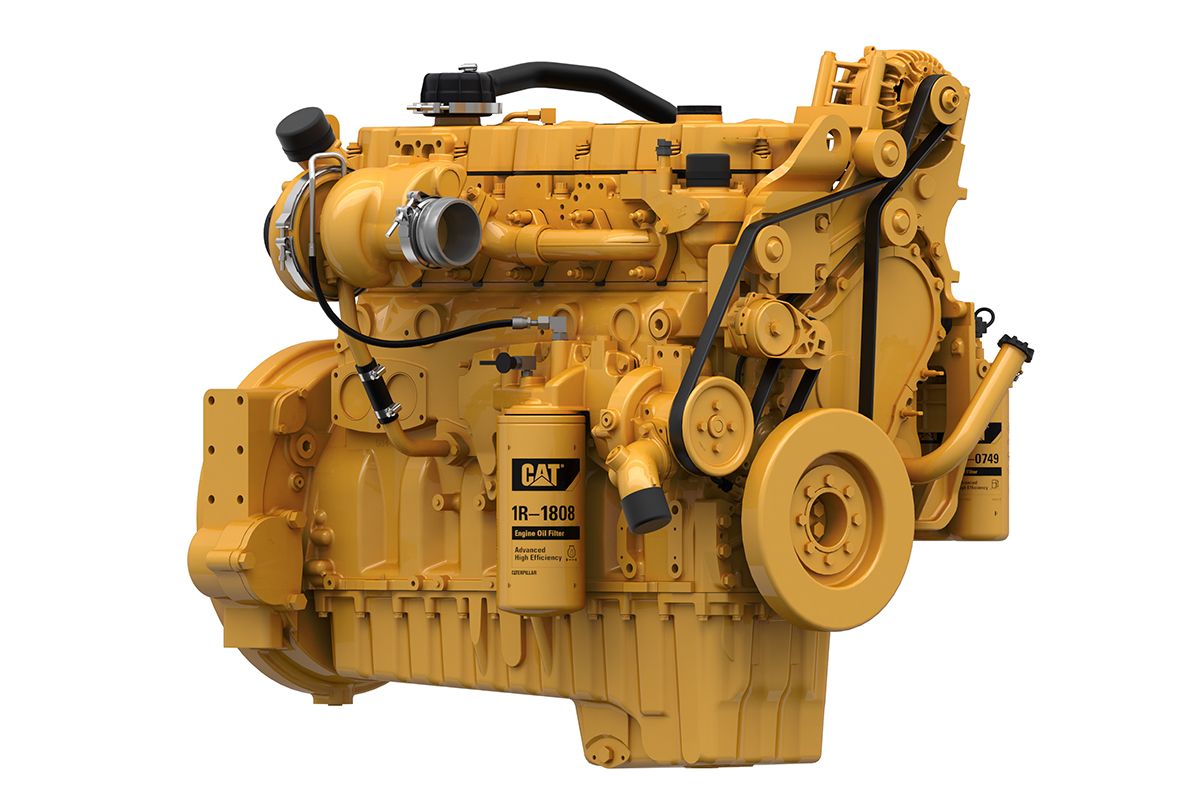

| Gross Power | 310 kW |

| Engine Model | Cat C9.3B |

| Fuel Tank Capacity | 1056 l |

| Length | 9.56 m |

| Width | 3 m |

| Maximum Height | 3.5 m |

| Wheel Base | 6.32 m |

| Ground Clearance | 500 mm |

Advantages and Features

Simple to Operate, Easy to Learn

- Easily match machine functions with gradation specifications through the 25 cm (10 in) color touch screen displays and push button controls

- Precise machine control is delivered through hand-wheel steering

- Controls are ergonomically located and grouped by function for quick and easy access

- Save time and ensure consistent depth for every cut with automatic features to exit and return to cutting depth

- Keyless push-button engine start can add security and convenience using Operator ID codes to recall saved operator preferences and profiles upon login

Boost Performance with Enhanced Visibility

- Standard FOPS cab with heating and air conditioning for a comfortable work environment

- Sight lines are optimized with the full left-to-right sliding cab

- A heated, 180º positioning air-ride suspension seat with fore and aft adjustment increases operator comfort and visibility

- Performance and safety can be augmented with standard and optional cameras that are viewed on large, in-cab displays:

- Fore and aft visibility is enhanced with standard front and rear mounted cameras

- Visibility to each side of the machine can be supplemented with optional side mounted cameras

- Obstacle avoidance and gradation results can be viewed with optional cameras mounted above the front and rear mixing chamber doors

Efficient Power with Increased Mobility

- Get 19% more power with the Cat® C9.3B engine that provides 310 kW (416 hp) of power and meets regional emission standards

- The overall machine length is 44 cm (17 in) shorter to enhance productivity and maneuverability in compact spaces

- Maximize traction and mobility with standard, electronically controlled all-wheel drive and four steering modes:Front wheels only, rear wheels only, crab steering, and coordinated steering

Deliver Superior Mix Quality

- Advanced electronic controls deliver ideal mix quality by keeping the rotor at the proper depth and the machine at an optimized speed

- Manage gradation for a wide variety of materials and applications with three separate rotor speeds that can be selected while in operation

- Easily modify material gradation by adjusting the front and rear mixing chamber doors, a simple gauge located on the LCD display keeps the operator informed of door position

- Rear rotor chamber door float feature simplifies operation and allows operator to select desired down pressure

- Work efficiently on a variety of reclamation and stabilization projects with three rotor options: Universal, Combination and Spade

Optional Spray Systems Deliver Precise Mix Quality

- Water and emulsion additive systems ensure mix design specifications are met

- Application rate of additives is accurately monitored through a computerized metering system

- A wide range of variable flow rates can be optimized for a variety of applications:

- Water flow rates from 30-1900 liters per minute (8-500 gallons per minute)

- Emulsion flow rates from 30-946 liters per minute (8-250 gallons per minute)

- Easily set up the spray system to deliver liquid additives according to specifications: manual or automatic, volume per m2 (yd2) or percent of material density

Easier Service, More Uptime

- Ground level access to routine maintenance items simplifies service and improves safety

- Auto-reversing cooling fan helps prevent debris build-up extending maintenance intervals for cleaning the cooling package

- Rotor drive system utilizes automated bearing lubrication

- Self-lubricating rotor chain drive is adjustment-free and eliminates routine maintenance

- Hydraulically-actuated rotor drive clutch does not require adjustment

- Built-in diagnostics monitor machine systems, alert the operator of performance issues and provide troubleshooting information

Standard Equipment

-

OPERATING ENVIRONMENT

- Adjustable armrests

- Air-ride, heated suspension seat

- Audio-ready with speakers

- Full width sliding cab with heat and air conditioning

- Push button start

- Illuminated dual-side access ladders

- High visibility retractable seat belt

- Mini-wheel steering control

- Multifunction propel lever

- Steering guides

- Color touch screen operator interface

-

POWERTRAIN

- Air to Air Aftercooler (ATAAC)

- Dual element air cleaner with pre-cleaner

- Extended life coolant with protection to -37 degrees C (-35 degrees F)

- On-demand fan with auto-reversing function

- Four steering modes

- All-Wheel Drive

- Electronic differential

- Oil-bath brake system

- Powertrain guard

-

ELECTRICAL SYSTEM

- 150 amp alternator

- 24-volt charging system

- Automotive-type fuse system

- Remote start/charge receptacle

- Two 1365 CCA maintenance-free batteries

-

ROTOR DRIVE SYSTEM

- Maintenance-free drive shafts

- Self-lubricating roller and bearings

- Shear disk driveline protection

- Automatic depth control

- Hydraulically-controlled dry clutch

- Three rotor speeds

- Variable volume mixing chamber

-

SERVICE AND MAINTENANCE

- Grouped filters with ground level access

- Cat Product Link™

- Remote Flash

- Remote access drains

- Ports for Scheduled Oil Sampling (S·O·S)

- Fluid level sight gauges

- Service light receptacles

- Toolbox

-

SAFETY

- Back-up alarm (front and rear)

- Front and rear facing cameras

- Ground level emergency shutdown switches (3)

- Horn (front and rear)

- ROPS

- Platform handrails and guardrails

- Mirrors

- Working lights (halogen or LED)

Optional Equipment

-

OPERATING ENVIRONMENT

- Additional color touch screen

-

POWERTRAIN

- Bio-friendly hydraulic oil

-

SPRAY SYSTEMS

- Water spray system

- Emulsion spray system

- Push bar

-

ROTOR DRIVE SYSTEM

- Torque limiter driveline protection

- Rotor - Universal 16

- Rotor - Universal 18

- Rotor - Combination

- Material sizing breaker bar

-

SERVICE AND MAINTENANCE

- Integrated air compressor

- Pneumatic bit removal tool

- Additional toolbox

-

SAFETY

- LED roading lights

- Folding LED safety beacon

- Folding side view cameras (2)

- Front and rear rotor chamber door cameras