Technicial Specifications

| Engine Power - ISO 14396:2002 | 93 kW |

| Engine Model | Cat® C4.4 |

| Net Power - ISO 9249 | 90 kW |

| Bore | 105 mm |

| Displacement | 4.4 l |

| Stroke | 127 mm |

| Emissions | Meets Brazil MAR-1 emission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA. |

| Note (1) | Net power advertised is the power available at the flywheel when the engine is equipped with fan, air intake system, exhaust system and alternator. |

| Note (2) | ¹Cat engines are compatible with diesel fuel blended with the following lower-carbon intensity fuels* up to: 20% biodiesel FAME (fatty acid methyl ester) or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations“ (SEBU6250) for details. * Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels. |

| Operating Weight Maximum | 15600 kg |

| Maximum Travel Speed | 37 km/h |

| Maximum Pressure - Implement Circuit - Normal | 35000 kPa |

| Maximum Pressure - Implement Circuit - Travel Circuit | 35000 kPa |

| Maximum Pressure - Auxiliary Circuit - Swing Mechanism | 25900 kPa |

| Main System - Maximum Flow - Implement | 245 l/min |

| Maximum Swing Speed | 11.5 r/min |

| Fuel Tank - Total Capacity | 250 l |

| Cooling System | 23 l |

| Engine Oil | 15 l |

| Hydraulic Tank | 98 l |

| Hydraulic System - Including Tank | 230 l |

| Rear Axle - Housing (Differential) | 11 l |

| Front Steering Axle - Differential | 9 l |

| Final Drive | 2 l |

| Powershift Transmission | 3 l |

| Boom | One-Piece Boom 4.65 m (15'3") |

| Stick | 2.5 m (8'2") |

| Bucket | GD 0.65 m³ (0.85 yd³) |

| Shipping Length | 7877 mm |

| Support Point | 3220 mm |

| Tail Swing Radius | 2190 mm |

| Counterweight Clearance | 1264 mm |

| Shipping Height with Falling Object Guard | 3250 mm |

| Machine Width with Blade with 10.00-20 tires | 2550 mm |

| Upperframe Width | 2490 mm |

| Height in Roading Position | 3970 mm |

| Boom Type | One-Piece Boom 4.65 m (15'3") |

| Stick | 2.5 m (8'2") |

| Bucket | GD 0.65 m³ (0.85 yd³) |

| Cutting Height | 8763 mm |

| Maximum Loading Height | 6378 mm |

| Maximum Digging Depth | 5091 mm |

| Vertical Wall Digging Depth | 4198 mm |

| Maximum Reach at Ground Line | 8312 mm |

| Note | The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1 kg (2.2 lb) of refrigerant, which has a CO2 equivalent of 1.216 metric tonnes (1.340 tons). |

Advantages and Features

Do More with Less Fuel

- The Cat® C4.4 engine meets Brazil MAR-1 emission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA.

- The M315 GC is fuel efficient to help keep you moving and productive on the job site.

- Travel between sites easily with travel speeds up to 37 kph (23 mph).

- Automatic Engine Speed Control helps reduce fuel consumption as it lowers engine speed when no operation is performed.

- The advanced hydraulic system provides the optimum balance of power and efficiency while providing the control needed for precise digging requirements.

- Auxiliary hydraulic options give you the versatility to use a wide range of Cat attachments.

- Don't let the temperature stop you from working. The wheeled excavator has a standard high-ambient temperature capability of 52°C (125°F).

Build Number: 05C

Low Maintenance Costs

- Quickly check and service your machine with daily maintenance points accessible from ground level.

- The hydraulic oil filter helps provide high filtration performance, anti-drain valves to help keep oil clean when the filter is replaced, and long life with a 2,000-hour replacement interval.

- Long greasing intervals and grouped grease points mean less downtime and more work getting done.

- Scheduled Oil Sampling (S•O•SSM) ports are located at ground level, helping simplify maintenance, and allowing for quick, easy extraction of fluid samples for analysis.

- Built on a long legacy of high performance and highly reliable wheeled excavators, our machine components are designed and manufactured to Caterpillar quality standards.

- Enjoy attachment commonality with the 313 GC, and common layout, systems, and parts with small excavators.

- A variety of attachments allow you to customize your machine to fit your needs. A long wheelbase undercarriage with parallel blade is available to help improve stability.

Work in Comfort

- Ergonomically designed cab with controls kept to a minimum, conveniently located and easy to operate.

- Rollover Protective Structure (ROPS) cab structure and Operator Protective Guards (top and front guards) are available.

- Get in and out of the cab easily using the tilt-up left console and straight access from the ground.

- Conveniently located storage for lunch box, documents, and mobile phones helping to keep the operator comfortable during the work day.

- Optional Bluetooth® radio allows for seamless mobile phone connection to listen to music and podcasts and for hands-free calling.

- Air conditioning controls are located on the machine display and can easily be adjusted to your ideal temperature with the touchscreen monitor.

Simple To Operate

- Start up the machine easily with the push-to-start button.

- Operate the wheeled excavator comfortably with easy-to-reach and intuitive controls.

- Two-way travel pedal is convenient and helps maximize productivity.

- Further boost productivity with blade control on the joystick and auto-axle lock.

- To help reduce operator fatigue, the auto-axle lock will activate automatically when the travel pedal is in neutral and the machine speed is near zero.

- Standard high-resolution 203 mm (8 in) touchscreen monitor features:

- Continuously improved user interface allows for intuitive navigation, helping minimize performance interruption with the easy-to-use touchscreen menu.

- Identify apps quickly with a grid list view, abbreviated app names, and categorized menu options.

- The notification center keeps important information visible to the operator and displays messages without shrinking the camera view.

- Color coded notifications set critical messages apart from the rest.

- Use the in-monitor QR code to learn about machine features through a full suite of “how-to” videos.

Safety Features

- Easy and safe access to daily service points.

- Standard LED lights give you a better view of your job site.

- The redesigned layout of the M315 GC helps provide improved right-side visibility compared to the M315. Rearview camera is standard.

- The service platform design provides easy, safe, and quick access to upper service platform; the service platform steps use anti-skid punch plate to prevent slipping.

- Grease points are grouped conveniently for quick and easy prevention lubrication.

- Use your PIN code on the monitor to enable the push button starting feature.

- The in-cab swing lock prevents front linkage from moving as you travel.

- Ground-level shutoff switch stops all fuel to the engine when activated and shuts down the machine.

- The ability to lock the main disconnect switch with a padlock helps protect the machine from unintentional use.

- Dedicated tie down points for safe truck transport.

Sustainability

- The Cat® C4.4 engine meets Brazil MAR-1 emission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA.

- Cat engines are compatible with diesel fuel blended with the following lower-carbon intensity fuels* up to: 20% biodiesel FAME (fatty acid methyl ester) or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details.

- Extended maintenance intervals not only reduce downtime but decrease the amount of fluid and filters that are replaced over the life of the machine.

- Auto Engine Speed Control reduces fuel burn and greenhouse gas emissions by allowing the engine to automatically go into idle mode when the machine is not working. Consult your Cat dealer or the machine's operation and maintenance manual for more information.

Standard Equipment

-

Technology

- VisionLink®

-

Electrical System

- LED lights on boom and cab

- Roading and indicator lights, front and rear

- Maintenance free batteries

- Centralized electrical disconnect switch

-

Engine

- Cat® C4.4 single turbo diesel engine

- Power mode selector

- One-touch low idle with automatic engine speed control

- Automatic engine idle shutdown

- Work up to 3000 m (9,842 ft) above sea level without engine power de-rating

- 52° C (125° F) high-ambient cooling capacity

- Cold starting capability for –18° C (0° F)

- Double element air filter with integrated pre-cleaner

- Electric fuel priming pump

-

Hydraulic System

- Boom and stick drift reduction valves

- Electronic main control valve

- Element type main hydraulic filter

- Automatic swing brake

- Adjustable hydraulic aggresiveness

-

Safety and Security

- Rear-view camera

- Signal/warning horn

- Neutral lever (lock out) for all controls

- Ground-level accessible secondary engine shutoff switch in cab

- Anti-skid plate and countersunk bolts on service platform

-

Service and Maintenance

- Scheduled Oil Sampling (S·O·S℠) ports

-

Undercarriage and Structures

- All wheel drive

- Automatic brake/axle lock

- Creeper speed

- Electronic swing and travel lock

- Heavy-duty axles, advanced disc brake system and travel motor, adjustable braking force

- Oscillating front axle, lockable, with remote greasing point

- 10.00-20 16 PR, dual tires

- Steps, left and right, with tool box in undercarriage

- Two-piece drive shaft

- Two speed hydrostatic transmission

- Fenders, front and rear, steel

- 2600 kg (5,730 lb) counterweight

Optional Equipment

-

Note

- Standard and Optional Equipment may vary. Consult your Cat dealer for details.

-

Boom, Sticks and Linkages

- 4.4 m (14'5") One-piece short boom

- 4.65 m (15'3") One-piece boom

- 2.2 m (7'3'') stick

- 2.5 m (8'2") stick

- Bucket linkage; 312-type without lifting eye

-

Electrical System

- LED lights on chassis and counterweight (left and right-hand-side)

- 1-slider joystick

- Electrical refueling pump

-

Engine

- Radiator screen

-

Hydraulic System

- Advanced Tool Control (one/two way high-pressure flow)

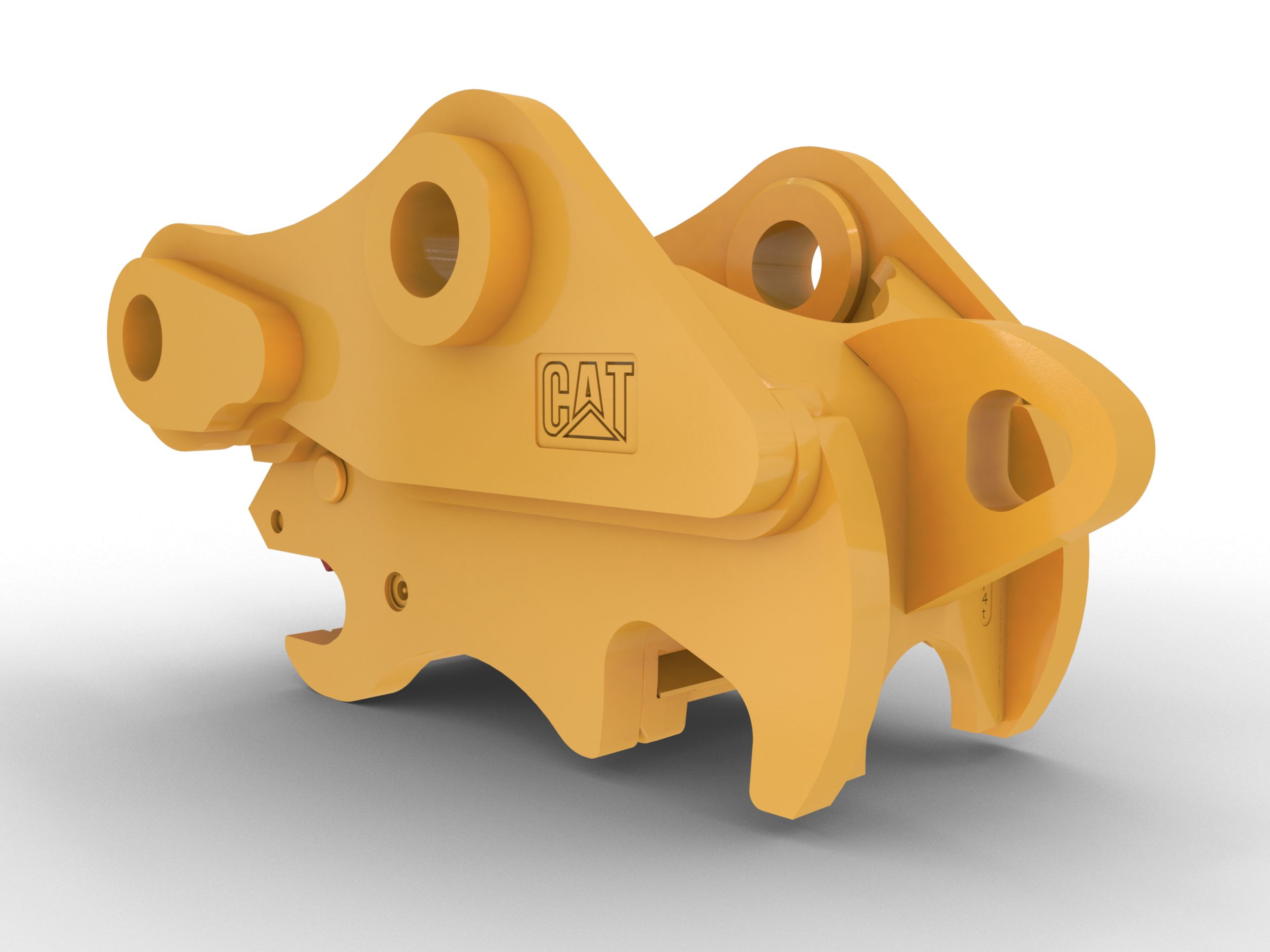

- Quick coupler circuit for Cat Pin Grabber and CW dedicated

- Boom and stick lowering check valves

-

Safety and Security

- Right-side-view camera

- Travel alarm

- Rotating beacon on cab and chassis

- Cat Asset tracker

- Operator Protective Guards (OPG)

-

Undercarriage and Structures

- Drive shaft guard