Technicial Specifications

| Engine Model | Cat® C18 ACERT™ |

| Net Power | 390 kW |

| Bore | 145 mm |

| Stroke | 183 mm |

| Displacement | 18.1 l |

| Direct Drive - Flywheel Power | 349 kW |

| Converter Drive - Flywheel Power | 372 kW |

| Net Power - EEC 80/1269 | 373 kW |

| Direct Drive - Gross Power | 414 kW |

| Net Power - ISO 9249 | 390 kW |

| Converter Drive - Gross Power | 413 kW |

| Operating Weight | 49546 kg |

| Converter Drive - Forward 1 | 6.8 km/h |

| Converter Drive - Forward 2 | 11.6 km/h |

| Converter Drive - Forward 3 | 20.3 km/h |

| Converter Drive - Reverse 1 | 6.8 km/h |

| Converter Drive - Reverse 2 | 12.2 km/h |

| Converter Drive - Reverse 3 | 21.4 km/h |

| Direct Drive - Forward 2 | 12.4 km/h |

| Direct Drive - Forward 3 | 22.1 km/h |

| Direct Drive - Reverse 1 | 7.2 km/h |

| Direct Drive - Reverse 2 | 13 km/h |

| Direct Drive - Reverse 3 | 23 km/h |

| Converter Drive - Reverse 4 | N/A |

| Converter Drive - Forward 4 | 35.4 km/h |

| Direct Drive - Reverse 4 | N/A |

| Direct Drive - Forward 1 | Lock Up Disabled |

| Direct Drive - Forward 4 | 38.5 km/h |

| Cooling System | 107 l |

| Crankcase | 60 l |

| Transmission | 83 l |

| Hydraulic Tank | 137 l |

| Differential - Final Drives - Front | 186 l |

| Differential - Final Drives - Rear | 190 l |

| Fuel Tank | 793 l |

| ROPS/FOPS | Meet SAE and ISO standards |

| Sound Performance Levels | Meets ANSI/SAE, SAE and ISO standards |

| Cab | Integrated Rollover Protective Structure (ROPS)/Falling Object Protective Structure (FOPS) standard |

| Front | Planetary-Fixed |

| Oscillating Rear | ±6 |

| Brakes | Meet SAE/ISO 3450 1996 |

| Doze | 54 m³ |

| Carry | 27 m³ |

Advantages and Features

Productivity

Purpose Built Front Linkage

Cat wood chip scoops have the unique capability of maximizing your production by both dozing and carrying a load with each pass. A purpose built hydraulic system is optimized for use with this work tool to maximize machine productivity and efficiency.

Auto Idle Kickdown (AIK)

If an operator is not actively operating the machine for a period of time, the AIK system will temporarily reduce the engine speed to save fuel. After an automated engine speed reduction, the system will automatically resume the engine speed to the previous setting when the operator engages the implement control pod of the F-N-R switch to the STIC™ Steer.

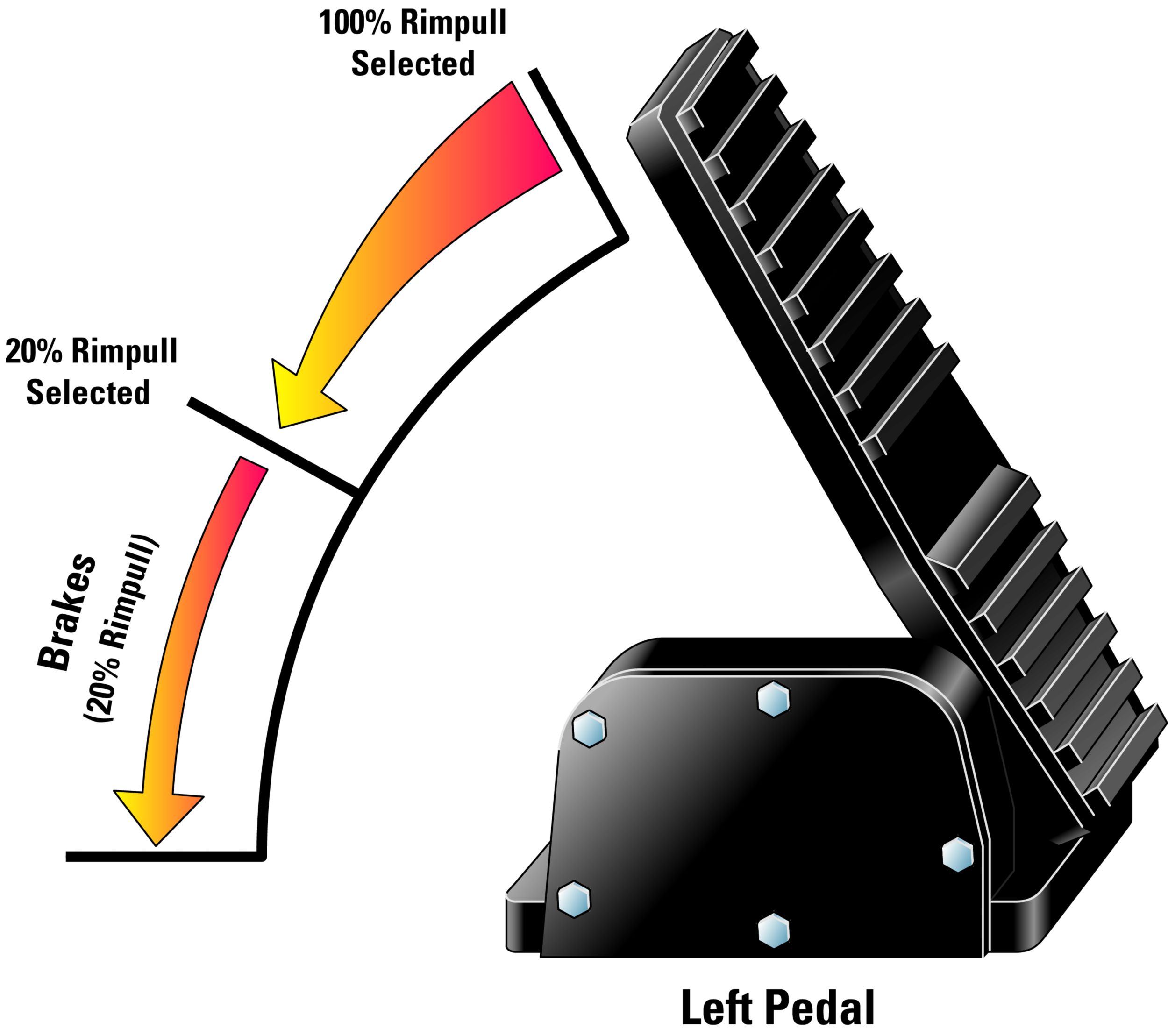

Impeller Clutch Torque Converter (ICTC) Left Pedal Control

The ICTC works with throttle lock to allow the operator to modulate rimpull to the wheels and slow the machine down without reducing engine speed. This allows the machine to maintain full hydraulic power for blade and steering control which gives the 834H a hydrostatic feel while keeping the benefits of the world's most efficient and powerful drive train and powershift transmission with lock-up control system.

Oscillating Rear Axle

The fixed front, oscillating rear axle ensures four-wheel ground contact for optimum traction and stability. The front axle is rigidly mounted to the front loader frame, while the rear axle is allowed to oscillate. This configuration allows the operator's view of the scoop to remain constant as the rear axle oscillates enabling the operator to maintain a smooth and properly graded work area in any underfoot conditions.

Load Sense Steering

The steering system utilizes a variable displacement pump for maximum machine performance by directing power through the steering system only when needed. This improves efficiency and reduces heat build up.

Reliability

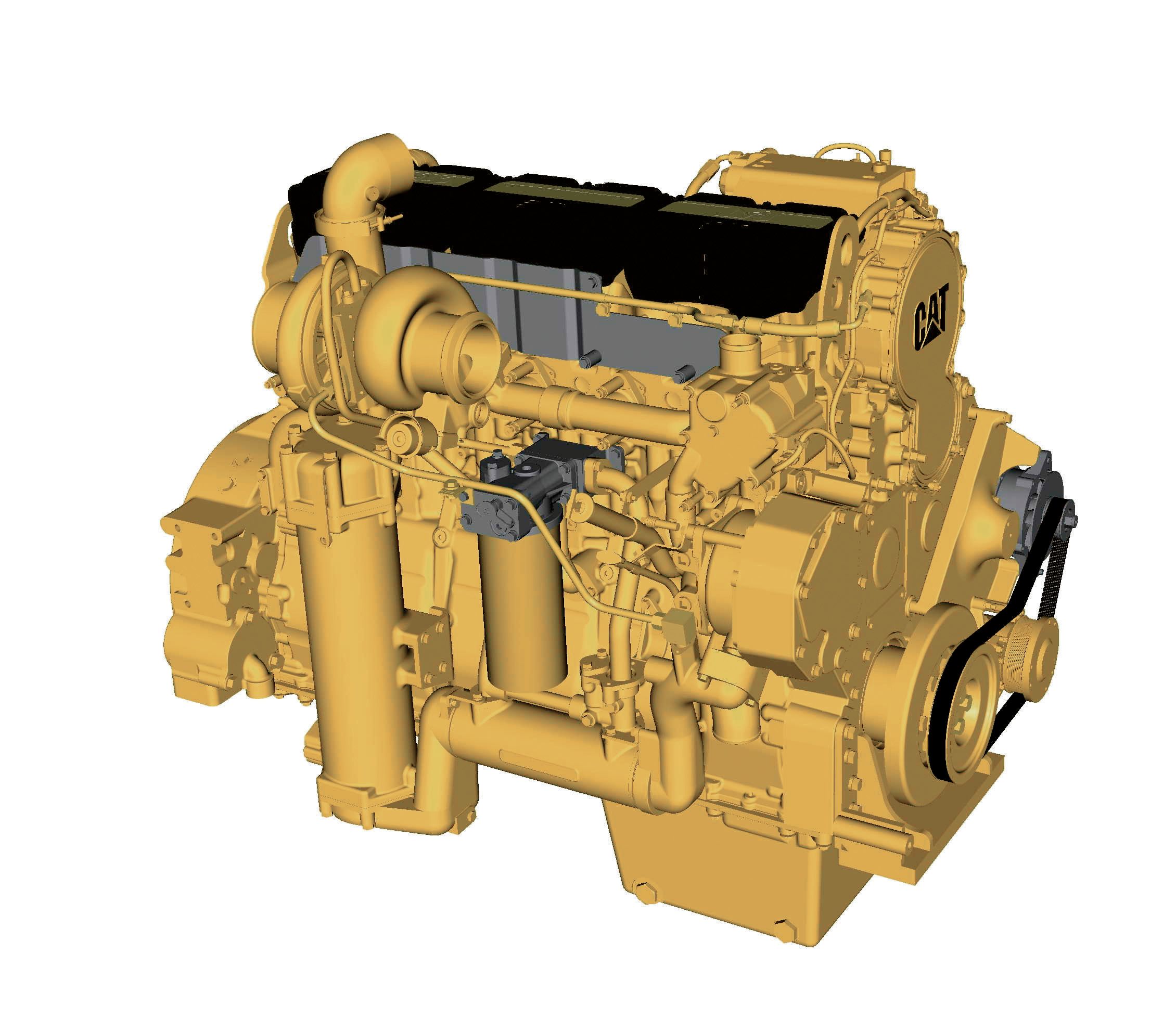

Cat C18 engine with ACERT™ technology

The Cat C18 engine with ACERT technology is U.S. EPA Tier 3 and EU Stage III compliant. It features increased horsepower and efficient fuel management for quick response, high productivity and exceptional service life. A sculptured cylinder block provides greater strength and is lighter weight.

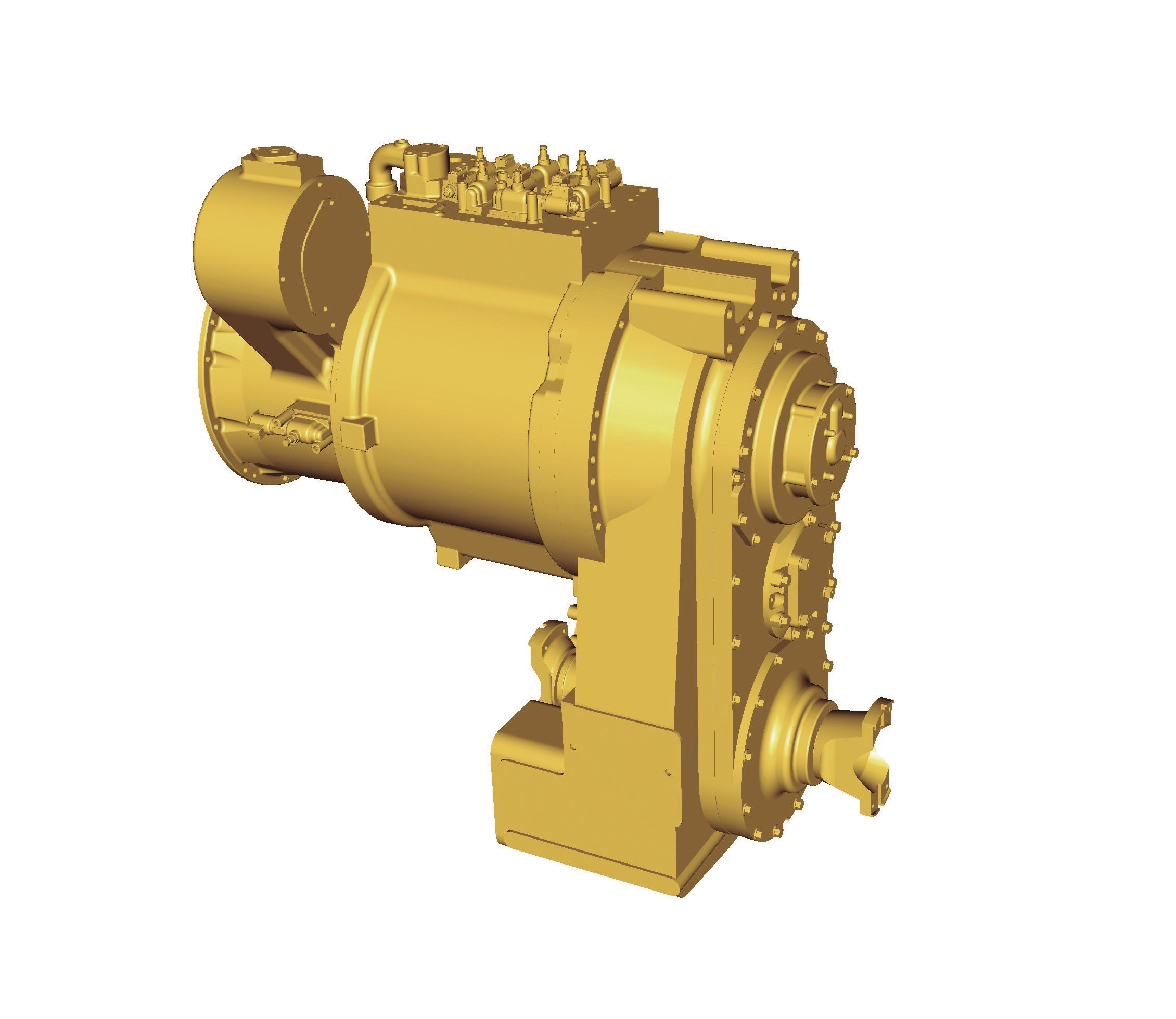

Cat Planetary, Power Shift Transmission

Electronic shifting provides smooth, consistent shifts. Large diameter clutches coupled with four planet gear trains provide added durability for extended, trouble free life.

Structures

Combining the use of robotic welding and castings in critical high stress areas, more than 80 percent of the machine structure is robotically welded to provide highly consistent welds and increased strength. Castings are also used in several areas to increase strength by helping spread the loads and reduce the number of parts.

Axle-Shaft, Oil Disc Brakes

These brakes are adjustment free, fully hydraulic and completely sealed. Disc face grooves provide cooling even when brakes are applied for a longer component life.

- Location of brakes allow for improved serviceability. The axle shaft brake design allows for brake service while leaving the final drive intact.

- Axle-shaft brakes require less force by operating on the low torque side of the axle. Combined with improved axle oil circulation for increased cooling, the oil-enclosed, multiple disc brake design improves durability.

Safety

Entry and Exit

Getting on and off the machine is one of the leading causes of injury on a job site. Cat wood chip scoops have a number of features to ensure your operator gets safely on and off the machine. They include primary and secondary stairwell exits, punch stamped tread plates, ground level nighttime stairwell light switch, full perimeter railings on upper platforms, side platform emergency egress and toe kicks and optional roading fenders.

Rearview Camera

With the new optional rearview camera, visibility is greatly enhanced. The camera is located in a pocket on the grill to protect it from damage and the elements. The camera can be set to activate only when the transmission is in reverse to help eliminate distractions in the cab, especially when in dark environments.

Visibility

Cat wood chip scoops offer a number of standard and optional features to enhance job site visibility. Standard and optional features include long life LED lights, articulated wiper/washer system with intermittent features, front walk around platform for easy windshield cleaning access, optional rear vision camera, optional high intensity discharge lights, optional warning beacon and optional turn signals.

Serviceability

Optional Swing Out Radiator Fan

The optional swing out radiator fan provides for easy access to the radiator cores for easy cleaning and inspection.

Auto Reversing, Hydraulically Driven Demand Fan

The demand fan automatically adjusts fan speed for optimal cooling, resulting in reduced power draw on the engine, better fuel efficiency and more power for hydraulics and rimpull. The fan reverses automatically at preset intervals to remove debris from the inlet screen. It can also be reversed manually from the cab.

Component Access

Swing out doors on both sides of the engine compartment provide easy access to the engine oil dipstick and filler spout, S·O·SSM ports, fuel filters air conditioner compressor, engine oil filters, alternators, starting receptacle, air filter service indicator, cooler fill and ether starting aid. There are also ground level viewable sight gauges on all major systems and centralized remote pressure taps.

Shutdown and Lockout Features

An electrical disconnect switch and hydraulic lockout switch allow service technicians to perform maintenance while the machine stays static. Other shutdown or lockout devices include ground level engine shutdown and ground level steering hitch lock lever.

Operator Comfort

A comfortable operator is a productive operator, which is why Caterpillar has designed the 834H with a best-in-class working environment for this size scoop. The world class cab incorporates features for operator comfort and ergonomics, visibility and ease of operation. An updated Implement Pod is fully adjustable and designed for low-effort comfort. Switches and controls are located within easy reach of the operator. Interior noise levels are reduced to a quiet 73 dB(A). Options include heated seat for cold weather operations and Bluetooth, MPS, or satellite radio options.

STIC Steering System

The STIC steer controller uses a single lever for steering and transmission control. Left-hand operations enable the operator to shift and change directions without letting go of the steering controls.

Idle Shutdown

This new feature will automatically shutdown the engine after the machine has been in a safe idling state for an extended amount of time. The operator in the cab will be audibly and visually warned before the shutdown occurs.

Customer Support

Selection

Cat dealers can help customers compare and choose the right machine for their business.

Financing

Cat dealers offer financing options to meet a variety of needs.

Operation

Improve operating technique for better productivity and profit with the latest Cat dealer training resources.

Product Support

Cat dealers are with customers every step of the way with unsurpassed worldwide parts support, trained technicians and customer support agreements.

Standard Equipment

-

ELECTRICAL

- Alarm, back-up

- Alternator (100-amp)

- Batteries, maintenance-free

- Deutsch terminal connectors

- Electrical system (24-volt)

- Lighting system, halogen (front and rear), access stairway

- Starter, electric (heavy-duty)

- Starting receptacle for emergency starts

-

OPERATOR ENVIRONMENT

- Air conditioner

- Cab, sound suppressed and pressurized

- Internal four-post rollover protective structure

- (ROPS/FOPS), radio ready (entertainment) includes antenna, speakers and converter (12-volt, 15 amp), 12-volt power port, tinted glass

- Cigar lighter (12-volt, 15-amp) and ashtray

- Coat hook

- Electro-hydraulic lift, tilt and dump

- Heater and defroster

- Horn, electric

- Light, cab (dome)

- Lock-up clutch disable switch

- Lunch box and beverage holders

- Monitoring system (EMS-III)

- Action alert system, three category

- Instrumentation, gauges:

- Instrumentation, warning indicators

- Mirrors, rearview (externally mounted)

- Rimpull select switch

- Seat, Comfort Series (cloth), air suspension

- Seat belt, retractable, 76 mm (3 in) wide

- STIC control system with steering lock

- Tilt and lift control system lock

- Transmission gear indicator

- Wet-arm wipers/washers (front and rear)

- Intermittent front wiper

-

POWER TRAIN

- Brakes, full hydraulic, enclosed, wet-disc

- Multiple disc service brakes

- Case drain filters

- Demand fan

- Fuel priming pump (electric)

- Parking brake

- Precleaner, engine air intake

- Radiator, Next Generation Modular Radiator (NGMR)

- Separated cooling system

- Starting aid (ether) automatic

- Throttle lock

- Torque converter, impeller clutch with lockup control system and rimpull control system (switch and dial in cab)

- Transmission, planetary, autoshift (4F/3R)

-

OTHER STANDARD EQUIPMENT

- Doors, service access (locking)

- Engine, crankcase, 500 hour interval with CH-4 oil

- Grouped Electronic Clutch Pressure Control, remote mounted pressure taps

- Hitch, drawbar with pin

- Hood, metallic with lockable service doors

- Hydraulic oil cooler

- Muffler (under hood)

- Oil sampling valves

- Steering, load sensing

- Vandalism protection caplocks

- Venturi stack

-

TIRES, RIMS AND WHEELS

- A tire must be selected from the mandatory attachments section - base machine price includes a tire allowance

-

ANTIFREEZE

- Premixed 50 percent concentration of Extended Life Coolant with freeze protection to -34° C (-29° F)