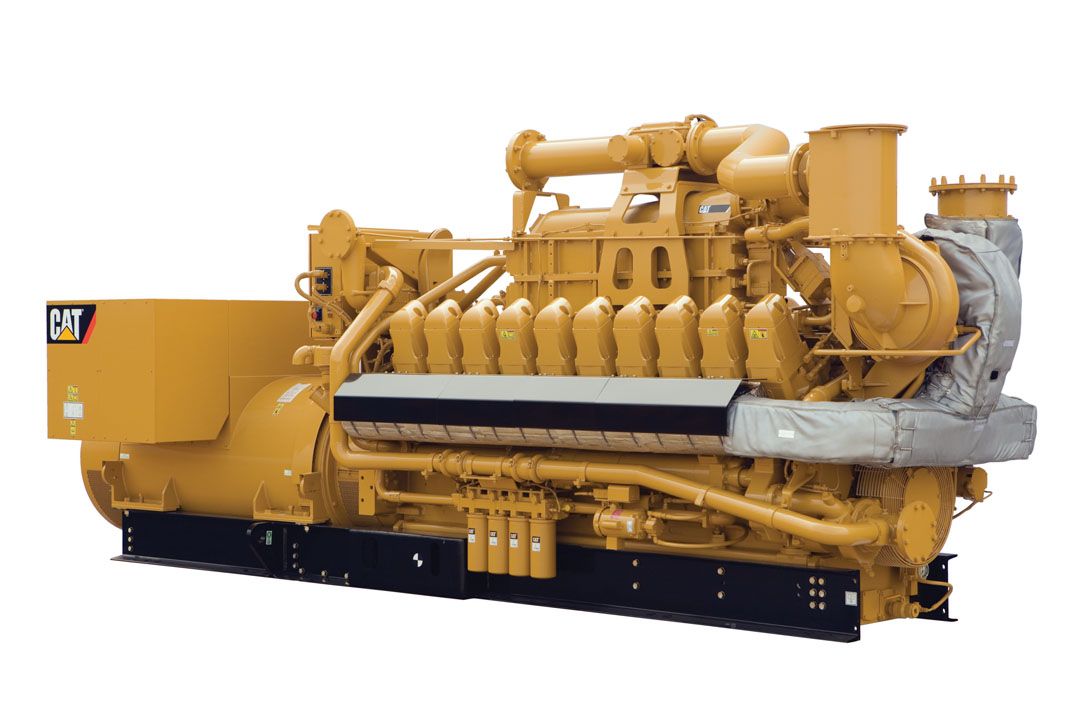

Technicial Specifications

| Continuous Rating | 2022 ekW |

| Fuel Type | Natural Gas |

| Maximum Electrical Efficiency | 41.50% |

| Maximum Standby Rating | 2022 |

| Frequency | 50 |

| RPM | 1500 |

| Engine Model | G3520E |

| Displacement | 86 l |

| Aspiration | TA |

| Bore | 170 mm |

| Stroke | 190 mm |

| Fuel System | Natural Gas |

| Compression Ratio | 11.9 |

| Length | 6893 mm |

| Width | 2001 mm |

| Height | 2727 mm |

| Dry Weight - Genset | 17826 kg |

Advantages and Features

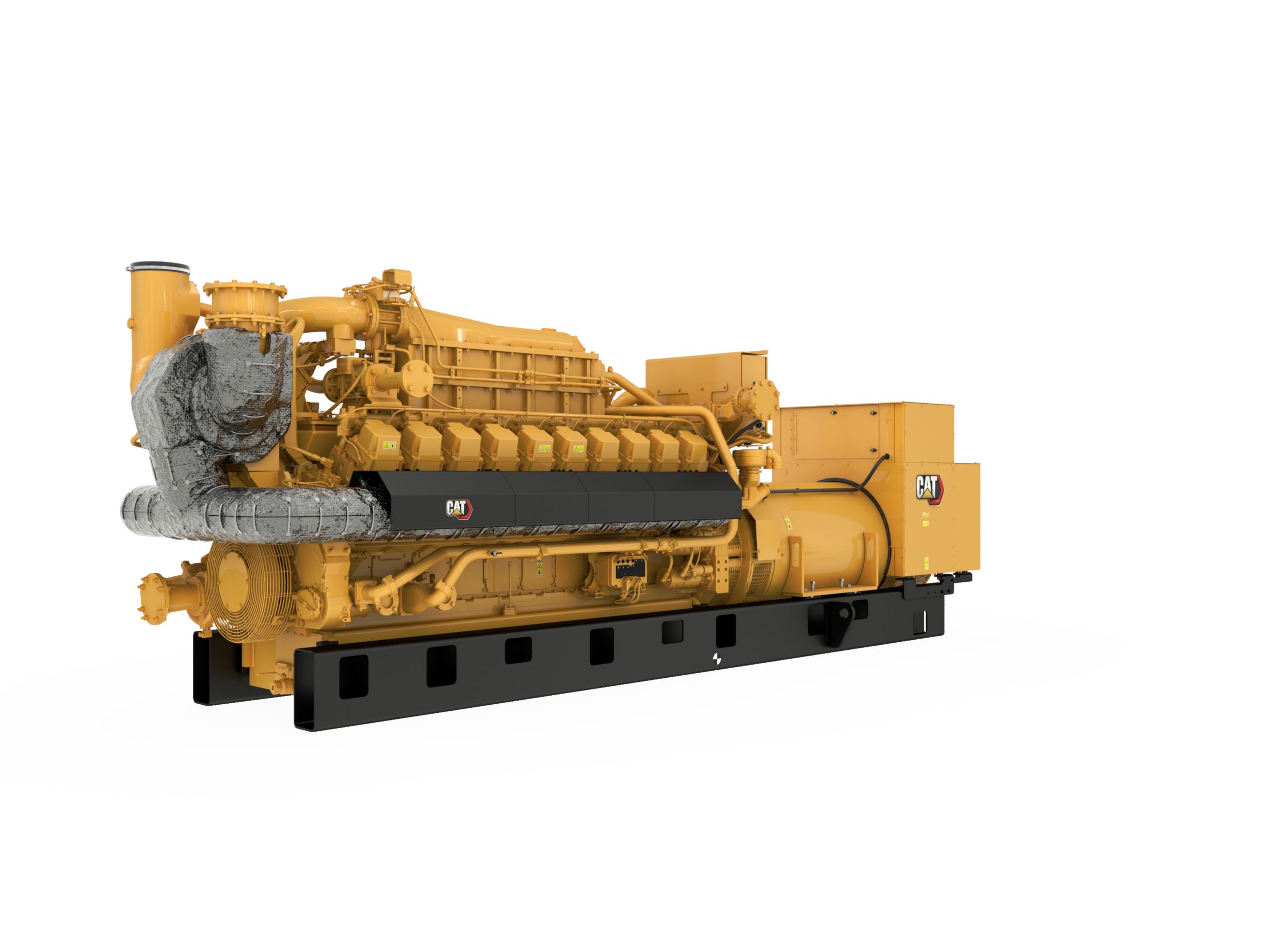

Cat G3520E Gas Engine

- Robust high speed block design provides prolonged life and lower owning operationg costs

- Designed for maximum performance on low pressure pipeline natural gas

- Simple open chamber combustion system for reliability and fuel flexibility

- Leading edge technology in ignition system and air/fuel ratio control for lower emission and engine efficiency

- One electronic control module handles all engine functions: ignition, governing, air/fuel ratio control and engine protection

SR5 Generator

- Designed to match performance and output characteristics of Caterpillar gas engines

- Industry leading mechanical and electrical design

- High efficiency

EMCP 4.3 Control Panel

- User-friendly interface and navigation

- Scalable system to meet a wide range of installation requirement

- Expansion modules and site-specific programming for specific customer requirements

Cat Electronic Control System

- Simple user friendly interface and navigation

- Digital monitoring, metering and protection setting

- Fully-featured power metering and protective relaying

- Remote control and monitor capability options

Cooling System

Emissions

- Meets most worldwide emissions requirements down to 0.5 g/bhp-hr NOx level without aftertreatment

Proven System

- Field proven in a wide range of applications worldwide

- Fully prototype tested

- Certified torsional vibration analysis available

Full Range of Attachments

- Wide range of bolt-on system expansion attachments

- Factory designed and tested

- Flexible packaging options for easy and cost effective installation

World Wide Product Support

- Cat dealers have over 1,800 dealer branch stores operating in 200 countries

- Your local Cat dealer provides extensive post-sale support, including maintenance and repair agreements

Standard Equipment

-

Control Panel

- EMCP 4.3

-

Air Inlet

- Two-element single-stage air cleaner with enclosure and service indicator

-

Cooling

- Standard CAT Flange

- Right-Hand/Left-Hand Outlet Connections

- Engine driven water pumps for jacket water and aftercooler

- ANSI/DN adapter flange connections

-

Exhaust

- Individual exhaust port and turbocharger outlet wired to Integrated Sensing Module (ISM) with Gas ECM providing alarms and shutdowns

- Dry exhaust manifolds, insulated and shielded

-

Fuel System

- Fuel system is sized for 31.5 to 47.2 MJ/NM3 dry pipeline natural gas with pressure of 10.2 to 34.5KPa to the engine fuel control valve

- Fuel filter

- Engine installed, fuel metering valve

- 24V ETR Gas Shutoff Valve

- Throttle plate, 24V DC actuator, controlled by GECM

-

Ignition System

- Individual Cylinder Detonation Sensitive Timing (DST)

- Electronic Ignition System (controlled by GECM)

-

Generator

- SR4B

- Caterpillar's Digital Voltage Regulator (CDVR) with 3-phase sensing and KVAR/PF control

- Busbar connections

- SR5

- Winding temperature detectors

- Permanent Magnet Excitiation

- Anti-condensation space heater

- 3-phase brushless, salient pole

-

General

- RH Service

- Crankshaft vibration damper and guard

- Paint - Caterpillar Yellow except rails and radiators gloss black

Optional Equipment

-

Air Inlet

- Heavy duty air cleaner

- Regular duty air cleaner

- Air cleaner with precleaner

- Mounting stand

-

Contol Panel

- Local NFPA99-110 Alarm Module w/LEDs

- PL1000E/PL1000T Communications Module

- Remote 24V-32V 8/16 Light Annunciator

- Custom 8-Light Alarm Module

- Engine Failure Relay

- Synchronizing Module

-

Control Panels

- Local alarm module

-

Cooling

- Jacket water coolant heater

- Cat Flange, ANS/DIN Adapter Flange

- Engine Pumps

- Aftercooler air lines, aftercooler core replacement

- Inlet/Outlet connections

-

Exhaust

- 15/18/25 dBA Muffler Attenuation

- 305/356mm Flange/Exhaust Expanders, 305/406mm Flange and Exhaust Expander

- 356-406mm Flange and Exhaust Expander

- Mufflers (15/18/25 dBA Attenuation) and spark-arresting muffler with ANSI companion flanges

- 305/360/406 mm Elbow Kits

- Flexible Fittings

- 16" Spark Arresting Muffler

-

Fuel System

- Gas Train (31.5 MJ/Nm3 with inlet pressure 19.2 to 48.3 kPa (2.78 to 7 psi))

- Gas Train 0-100 kPag, 4-20mA pressure sensors

- Fuel Filter, Gas Filter

- 24VDC Gas Shutoff Valve, Gas Knockdown Regulator

-

Generator

- Annunciator modules

- Air filters, cable access box

- Bearing temperature detectors

- Low voltage extension box

- 16 Point/32 light annunciator with NFPA99-110/CSA282 configuration

- Extension box, European bus bars

- Generator air filter

- Medium and high voltage generators and attachment

- 415/400/380, 3300/6600/11000 Volt Generator Options (50 Hz)

- 480/4160/13200 Volt Generator Options (60 Hz)

- 8/15/23M harness

- 8.7/15 kV Cross, Differential, Current Transformers (CCCT, DCT, CT)

- Cable access box

-

Governing System

- Load share module

-

Starting/Charging

- Battery diconnect switch

- 45A, 24V charging alternator (requires engine driven pumps)

- 24V Starting Motors

- 20A Battery Charger

- Battery with cables and rack (shipped loose)