Технические характеристики

| Net Power - ISO 9249 | 171 kW |

| Engine Model | Cat® C7.1 ACERT™ |

| Operating Weight | 21122 kg |

| Bucket Capacities | 7.60 m³ (10.00 yd³) |

| Maximum Gross Power - SAE J1995 | 187 kW |

| Note (2) | The power ratings apply at the stated speed when tested under the reference conditions for the specified standards. |

| Maximum Net Power - SAE J1349 | 171 kW |

| Maximum Net Torque - SAE J1349 | 1163 N·m |

| Note (1) | Cat engine with ACERT Technology. |

| Peak Torque - Engine Speed | 1300 r/min |

| Maximum Power - Engine Speed | 2100 r/min |

| Maximum Gross Power - Engine Speed | 2100 r/min |

| Peak Gross Torque - Engine Speed | 1300 r/min |

| Maximum Net Power - ISO 9249 | 171 kW |

| Maximum Net Power - Engine Speed | 2000 r/min |

| Maximum Net Torque - Engine Speed | 1300 r/min |

| Bore | 105 mm |

| Engine Model | Cat C7.1 |

| Displacement | 7.01 l |

| Maximum Power - ISO 14396 | 186 kW |

| Maximum Net Torque - ISO 9249 | 1163 N·m |

| Peak Gross Torque - SAE J1995 | 1235 N·m |

| Peak Torque - ISO 14396 | 1231 N·m |

| Stroke | 135 mm |

| Note (3) | The net power advertised is the power available at the flywheel when the engine is equipped with fan, alternator, air cleaner and aftertreatment. |

| Note (4) | The gross power advertised is with the fan at maximum speed. |

| With Cooling Fan Speed at Maximum Value - Exterior Sound Pressure Level (SAE J88:2013)* | 75 dB(A) |

| FOPS | ISO 3449:2005 Level II |

| ROPS | ISO 3471:2008 |

| Note (1) | The sound values indicated below are for specific operating conditions only. Machine and operator sound levels will vary at different engine and/or cooling fan speeds. Hearing protection may be needed when the machine is operated with a cabin that is not properly maintained, or when the doors and/or windows are open for extended periods or in a noisy environment. |

| With Cooling Fan Speed at Maximum Value - Exterior Sound Power Level (ISO 6395:2008) | 107 dB(A) |

| Note (2) | *Distance of 15 m (49.2 ft), moving forward in second gear ratio. |

| With Cooling Fan Speed at Maximum Value - Operator Sound Pressure Level (ISO 6396:2008) | 70 dB(A) |

| Cooling System | 59 l |

| Transmission - Gear Box | 43 l |

| Engine Crankcase | 22 l |

| Fuel Tank | 275 l |

| Axles - Front | 43 l |

| DEF Tank* | 16 l |

| Axles - Rear | 43 l |

| Note | *Must meet the requirements outlined in ISO 22241-1 for Tier 4 Final/Stage IV models. |

| Hydraulic Tank | 125 l |

| Bore | 105 mm |

| Maximum Net Torque - ISO 9249 | 984 N·m |

| Maximum Gross Power - SAE J1995 | 196 kW |

| Maximum Net Torque - Engine Speed | 1400 r/min |

| Stroke | 135 mm |

| Displacement | 7.01 l |

| Peak Gross Torque - SAE J1995 | 1053 N·m |

| Maximum Power - Engine Speed | 2000 r/min |

| Note (2) | The power ratings apply at the stated speed when tested under the reference conditions for the specified standards. |

| Maximum Power - ISO 14396 | 195 kW |

| Peak Torque - ISO 14396 | 1050 N·m |

| Maximum Net Power - Engine Speed | 2000 r/min |

| Note (1) | Cat engine with ACERT Technology. |

| Note (3) | The net power advertised is the power available at the flywheel when the engine is equipped with fan, alternator, air cleaner and aftertreatment. |

| Engine Model | Cat C7.1 |

| Peak Torque - Engine Speed | 1400 r/min |

| Maximum Net Power - SAE J1349 | 185 kW |

| Maximum Net Torque - SAE J1349 | 984 N·m |

| Maximum Gross Power - Engine Speed | 2000 r/min |

| Maximum Net Power - ISO 9249 | 185 kW |

| Note (4) | The gross power advertised is with the fan at maximum speed. |

| Peak Gross Torque - Engine Speed | 1400 r/min |

| Maximum Working Pressure - Steering Pump | 23400 kPa |

| Maximum Flow - Steering Pump EH | 140 l/min |

| Note | Steering system uses a dedicated load sensing variable displacement pump with dual double acting cylinders. |

| Maximum Flow - Steering Pump HMU | 146 l/min |

| Front Axle | Fixed |

| Rear Axle - Traction Aid - Optional | Auto differential lock |

| Front Axle - Traction Aid - Optional | Auto differential lock |

| Note (3) | External caliper disc parking brakes mounted to the input shaft of the front axles. Since they are external, they do not have the inefficiencies of enclosed wet parking brakes due to brake discs running in oil nor is there any oil to change reducing fuel and maintenance costs. External caliper parking brakes are easily accessible for inspection and service. |

| Note (2) | The rear axle can oscillate to ±13 degrees helping to ensure all four wheels stay on the ground providing stability even in the roughest terrain for excellent stability and traction. |

| Rear Axle - Brakes - Service | Inboard wet disc |

| Rear Axle - Oscillation Angle by Tire Size - 23.5 R25 | ±13 degrees |

| Rear Axle - Traction Aid - Standard | Open differential |

| Rear Axle - Brakes - Park | Spring applied hydraulically released |

| Front Axle - Traction Aid - Standard | Manual differential lock |

| Rear Axle | Oscillating |

| Note (1) | M Series axles are designed to handle extreme applications resulting in reliable performance and durable life. |

| 3rd Function Maximum Flow | 240 l/min |

| Note (2) | Auxiliary third and fourth hydraulic functions can be easily added at the factory or in the field with the addition of a second remote valve. |

| Maximum Flow - Implement Pump | 286 l/min |

| Maximum Working Pressure - Implement Pump* | 29300 kPa |

| Note (3) | Ride control system now has two accumulators enabling it to be more effective over a greater payload range, increasing productivity and operator efficiency due to a better ride. |

| 4th Function Maximum Flow | 240 l/min |

| Note (4) | *Pressure is adjustable to set for specific tools and applications. Consult your local Cat dealer for further details. |

| 4th Function Maximum Working Pressure | 21780 kPa |

| Note (1) | Mono-block main hydraulic valve design reduces weight and has 40 percent fewer leak points than previous designs. |

| 3rd Function Maximum Working Pressure | 21780 kPa |

| Forward - 3 | 19.3 km/h |

| Reverse - 2 | 12 km/h |

| Forward - 4 | 25.7 km/h |

| Note (3) | Maximum travel speed in standard vehicle with empty bucket and standard L3 tires with 787 mm (31 in) roll radius. |

| Note (2) | Powershift transmissions also have a split-flow oil system which use new multi-viscosity oil to improve fuel economy. |

| Note (1) | Standard lock-up clutch torque converter matched with the engine power and hydraulics to improve performance and fuel efficiency. |

| Forward - 1 | 6.9 km/h |

| Reverse - 1 | 6.9 km/h |

| Reverse - 3 | 25.7 km/h |

| Forward - 2 | 12 km/h |

| Forward - 5 | 39.5 km/h |

| Equivalent to Tier 3/Stage IIIA | 196 kW |

| U.S. EPA Tier 4 Final/EU Stage IV | 187 kW |

Преимущества и особенности

Reliable – Proven Components and Technology You Can Count On

Every Tier 4 Final/Stage IV, or equivalent to Tier 3/Stage IIIA engine is equipped with a combination of proven electronic, fuel, air and aftertreatment components, if required.

More Powerful, Reliable Engine Electronics

The electronics used in Tier 4 Final/Stage IV or equivalent Tier 3/Stage IIIA engines are more powerful and robust than ever. Increased features and connection commonality improve the customer experience and increase quality and reliability. Over-foam wiring harness adds to reliability even in the most demanding applications.

Hydraulics

The M Series hydraulic systems have significant design changes and customer value improvements. The main hydraulic valve is a mono-block with an integrated ride control section. The mono-block design reduces weight, has fewer leak points, and is common across all M Series models. Auxiliary hydraulic functions can be easily added at the factory or in the field with the addition of a second remote valve.

Equipment Monitoring

Cat Connect technologies and Cat dealer services take the guesswork out of equipment management. Product Link™ and the online VisionLink® application enable you to monitor real-time machine data and manage machine’s health. Your Cat dealer offers expert advice and S·O·SSM Services to maintain equipment reliability and efficiency.

Cold Start Package

The optional cold start package provides dependable starts in extreme cold weather and high altitudes.

Fuel Efficient – Engineered to Lower Your Operating Costs

Engine and Emissions

Cat ACERT engines are designed for maximum fuel efficiency and increased power density, while meeting Tier 4 Final/Stage IV emission standards, or emitting equivalent to Tier 3/Stage IIIA. This engine features innovative Cat electronics, a fuel injection process, air-management systems; an aftertreatment solution with Cat Selective Catalytic Reduction, and a fuel efficient regeneration system, if required.

Efficient Systems and Components

Innovative systems intelligently lower the average working engine speeds and reduce the overall system heat loads which result in significantly improved performance and fuel efficiency.

Advanced Systems with Innovative Integration

The deep system integration of the engine and emissions system, power train, hydraulic system and cooling system result in lower fuel consumption on average as compared to previous generation machines.

Productive Economy Mode

The productive economy mode automatically controls the engine torque and speed based on the machine’s power train load and places engine speed and torque in the most efficient operating range. The result is improved fuel efficiency while delivering optimal performance.

Tier 4 Final/Stage IV Engines

- Next Generation Fuel Systems – Cat injection timing precisely controls the fuel injection process through a series of carefully timed microbursts, providing more control of combustion for the cleanest, most efficient fuel burn.

- Cat NOx Reduction System – The Cat NOx Reduction System (NRS) captures and cools a small quantity of exhaust gas, then routes it back into the combustion chamber where it drives down combustion temperatures and reduces NOx emissions.

- Aftertreatment Technologies – To meet the additional 80 percent reduction in NOx emissions required by Tier 4 Final/Stage IV emission standards, the Selective Catalytic Reduction (SCR), has been added to the already proven Cat Tier 4 Interim/Stage IIIB aftertreatment solution.

Productive – Work Smart and Move More

Hydraulics

The ride control system has two accumulators enabling it to be more effective over a greater payload range, increasing productivity and operator efficiency.

Transmission

The power trains feature a lock-up clutch torque converter that has been matched with the engine power and hydraulics improving performance and fuel efficiency. These rugged transmissions have a split-flow oil system which uses new multi-viscosity oil to improve fuel economy.

Durable – Better Designed to Meet Your Needs

Frames

The robotically welded two-piece structural frame design provides strong and rigid structures. The M Series articulating hitch system, joining the front and rear frames, provides increased bearing force capacity.

Axles

The M Series axles are designed to handle extreme applications resulting in reliable performance and durable life. The rear axle can oscillate to ±13 degrees helping to ensure all four wheels stay on the ground providing stability even in the roughest terrain for excellent stability and traction.

Easy to Operate – Safe. Comfortable. Efficient.

Ensuring operators are safe, confident in the control of their machines, have a clean, comfortable and quiet operating environment with controls that are intuitive and low effort all contribute to lower operator fatigue and better performance.

Cab Access

A switch has been added to the electronic service center which unlatches the door remotely (optional). The gas strut then swings the door open all while the operator is safely on the ground. The angle of the steps up to the cab have been increased to an optimal fifteen degrees enabling operators to walk up like stairs versus climbing more vertically like a ladder. Grab handles have been repositioned so a secure three points of contact can be maintained at all times.

Visibility

Once in the cab, the new door securely seals against the new roll formed ROPS posts and the lower glass panel has been extended several inches to improve visibility to the left side of the machine. New larger convex mirrors improve visibility to the rear and integrated spot mirrors provide visibility close to both sides of the machine.

Sound

Viscous cab mounts connect the cab to the frame of the machine, decreasing noise and vibration the operator is subjected to. The result is a sustainable work environment and well-rested operator, remaining efficient and productive.

Central Display

The central display panel has a large text box, analog gauges, and LED warning indicators. The large text box provides in-language information about machine operation, feature activation and system troubleshooting and calibration. With the large analog gauges the operator can easily identify if key systems are within normal operating range.

Touch Screen Display

A new multipurpose color touch screen display dramatically simplifies the operator interface; with machine controls, rear vision camera and new fully integrated Cat Production Measurement system. Intuitive navigation with in-language text enables operators to modify certain machine operating parameters and monitor machine conditions literally at the touch of their fingers.

Control Panel

Sealed against moisture and dirt, the centralized switch panel with LEDs provides reliability and ready access to frequently required functions, even while wearing gloves. The ISO symbols located on each membrane switch are molded all the way through to ensure the image will not wear off over time.

The M Series maintains the “help” feature which explains the function of each membrane switch.

Focusing on operator efficiency, the control panel has been streamlined to include easy to reach highly utilized machine controls. The touch screen display enables the relocation of some expanded functions while eliminating the need for a second switch panel for further simplicity and easy machine operation.

Steering Wheel

The steering configuration on these machines offers a low-effort hand metering unit hydraulic steering system. Load sensing steering directs power through the steering system only when needed.

Electro-Hydraulic (EH) Joystick Steering with Force Feedback (Optional)

Operators will enjoy and quickly adopt the industry leading seat mounted EH joystick steering system, which provides precision control and dramatically decreases operator arm fatigue.

Implement Controls (EH)

Seat-mounted, single axis implement control levers (joysticks, optional) provide operators with precise control of the work tool, all while moving with the seat for maximum comfort. In-cab, programmable kick-outs and automatic cylinder snubbing are easy to set on-the-go for tilt, lower and lift, and are ideal for repeatable cycles.

Ride Control

The next generation of ride control works as a shock absorber, improving ride quality and smoothness over rough terrain, increasing operator confidence, comfort and efficiency, ensuring excellent material retention.

Integrated Technologies – Monitor, Manage, and Enhance Job Site Operations

Cat Connect makes smart use of technology and services to improve your job site efficiency. Using the data from technology-equipped machines, you’ll get more information and insight into your equipment and operations than ever before.

Cat Connect services are also available from your dealership including:

Equipment Management – increase uptime and reduce operating costs.

Productivity – monitor production and manage job site efficiency (applies to bucket applications).

Safety – enhance job site awareness to keep your people and equipment safe.

Consult your local dealer on the services available.

Featured Cat Connect technologies include:

LINK Technologies

LINK technologies wirelessly connect you to your equipment giving you access to essential information you need to know to run your business. Link data can give you valuable insight into how your machine or fleet is performing so you can make timely, fact-based decisions that can boost job site efficiency and productivity.

Product Link/VisionLink

- Product Link is deeply integrated into your machine to take the guesswork out of equipment management.

- Easy access to timely information like machine location, hours, fuel usage, idle time and event codes via the online VisionLink user interface can help you effectively manage your fleet and lower operating cost.

DETECT Technologies

DETECT technologies enhance operator awareness of the environment around working equipment and provide alerts to help keep people and assets safe.

Rear Vision Camera

- Integrated into standard display, enhances visibility behind the machine helping you work confidently.

- Optional second display can be added to provide a dedicated rear view of the job site.

Rear Object Detection (Optional)

- Integrated into touchscreen display, the radar system warns an operator of an object in critical zone while going in reverse.

- Increased awareness of the working environment enhances site safety.

Versatile – Do More Jobs with One Machine, Fusion Quick Coupler and Various Work Tools

Optimized Z-bar Linkage

Parallel lift capabilities, high lift, high tilt forces and versatility provide the optimal solution for millyard applications.

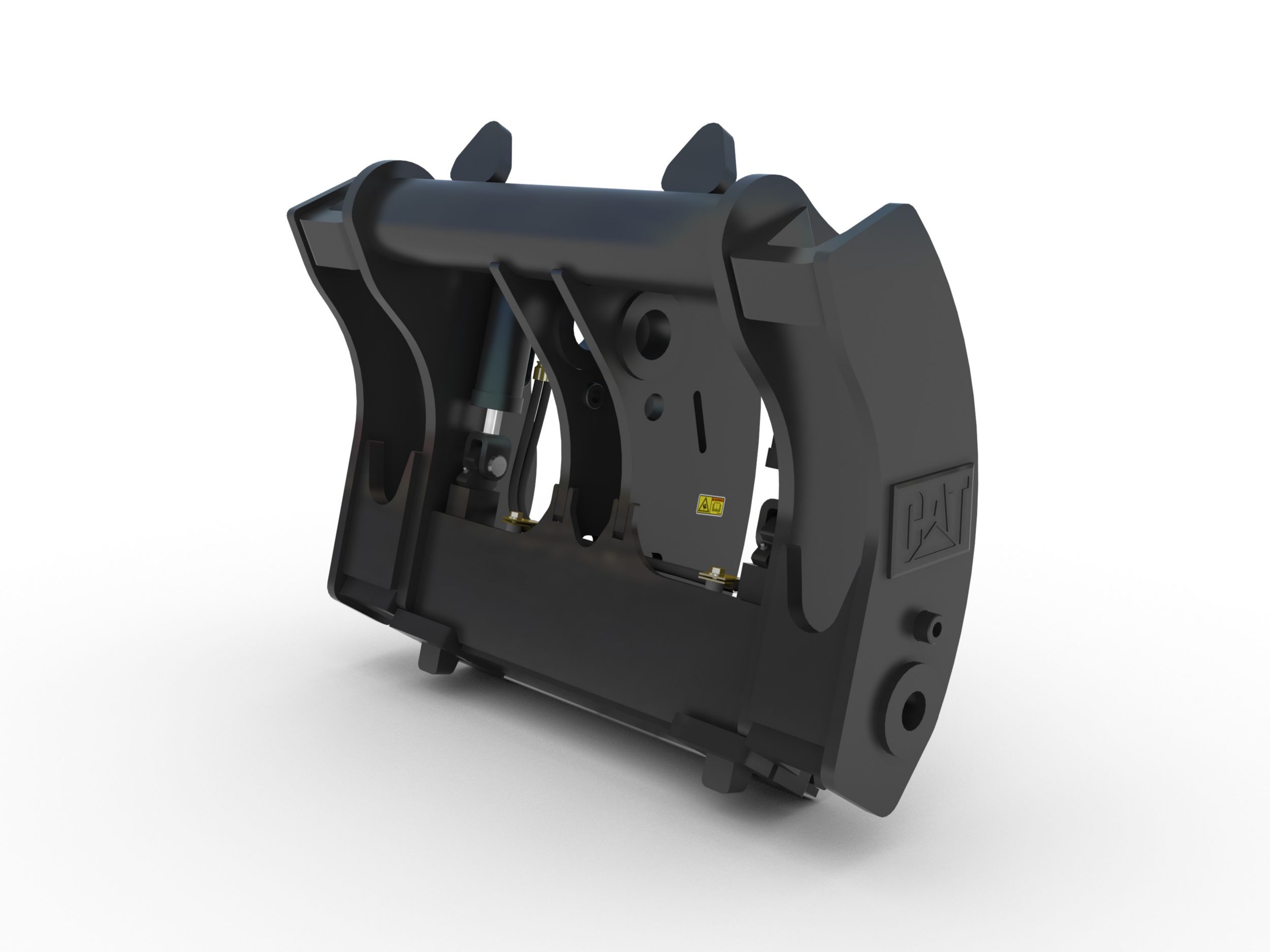

Fusion Quick Coupler – Maximum Machine Performance

Fusion is the patented wheel loader coupler system from Caterpillar. The Fusion Coupler System provides performance virtually identical to pin on – with all the flexibility of a quick coupler system. The Fusion Coupler sits back, close in to the loader arms – minimizing offset and increasing the machine’s performance.

Fusion Quick Coupler – Unsurpassed Durability

An advanced wedging mechanism creates a tight, rattle-free fit. This patented lock up system eliminates play and wear – resulting in a long service life.

Fusion Quick Coupler – Increased Visibility

An open coupler frame design clears sight lines from the operator’s seat, making it easier than ever before to engage and disengage attachments with certainty.

Fusion Quick Coupler – Common Interface Compatibility

The Fusion Coupler System not only allows one machine to use a range of work tools, but also allows one work tool to be picked up by machines of many different sizes.

Forks and Buckets

Millyard, Logging, and Log and Lumber Forks are designed to move wood in the millyard. Light Material, General Purpose and Material Handling Buckets are designed with Performance Series characteristics and bring fuel efficiency to load-and-carry work in the yard.

- Fusion™ Coupler: Fusion is the patented wheel loader coupler system from Caterpillar. The Fusion Coupler System provides performance virtually identical to Pin-On – with all the flexibility of a quick coupler system. The Fusion Coupler sits back, close in to the loader arms – minimizing offset and increasing the machine’s performance.

- Millyard Forks: Specially designed for millyard work, this fork style is ideal for unloading, sorting, decking and feeding logs to the mill.

- Grapple Forks: The new Sorting Grapple Forks and Unloading Grapple Forks are ideal for unloading and stacking timber. A rounded top clamp and frame open the interior profile of the fork, enabling larger capacity loads to be moved. Easy and gentle loading out of stacks is permitted by the short tines, while a large, broad clamp holds tight to short or long timber. Forks are available with a kick-out that unloads the fork even at full lift, enabling higher lumber stacking.

- Logging Forks: Feature a heavy-duty design for unloading and stacking heavy, tree-length wood.

- Log and Lumber Forks: Ideal for loading and unloading lumber, logs or palletized material.

- Pallet Forks: Handle a variety of banded or baled material. Fusion Pallet Forks feature an open frame design and offset tines for maximum visibility to the tines.

- Millyard Pole Forks: Optimized for pole yards, the Millyard Pole Fork features a refined frame profile and a top clamp that closes tighter to the frame. The result is positive, secure clamping of single poles as they are moved through the yard. The curved frame design promotes a rolling action of the logs for smooth loading and unloading.

- Woodchip Buckets: Extra capacity and loading characteristics and visibility windows make this bucket style perfect for handling woodchip.

- Performance Series General Purpose and Material Handling Buckets: Designed for loading, carrying, stockpiling and backfilling in a variety of applications and materials.

- High Dump Buckets: Fuel-saving design earns you more with every pass. Loads easily, dumps at any height for feeding mills and hoppers.

Check with your local Cat dealer for specific work tool attachments available in your region.

To extend the global portfolio of work tools designed for M/M XE Series machines, Caterpillar has an agreement with UFO that enables us to offer a selection of products in addition to Caterpillar Work Tools. The Millyard Tools are manufactured for the Europe, Africa and Middle East markets and manufactured in Sweden.

Application Specific Configuration – Maximize Performance and Productivity While Minimizing Operating Costs

Cooling System

An optional variable pitch fan automatically purges the cooler cores by periodically reversing the airflow when needed. This fan is beneficial in providing more airflow in the reverse direction (when compared to a system that simply reverses the fan rotation), which more thoroughly expels any debris build-up in the cooling cores. The variable pitch fan reduces the need for an air wand used to clean the backside of the cooler cores. For very high debris applications often found in millyards, consider pairing the variable pitch fan with optional high debris cooling cores for a robust solution and reduced maintenance.

An optional axle oil cooling system provides the capability to dissipate heat generated in high energy applications, such as braking with a large load or extended roading.

Air Systems

In conjunction with the standard strata precleaner, the optional turbine engine precleaner extends filter element life and helps to provide clean air to the engine in high debris applications by ejecting saw dust and similar material before it ever reaches the air cleaner. Similar in function, a Cat Advanced Cabin Filtration (ACF) precleaner is also available to extend service intervals of the cabin filter.

Guarding

Depending on the level of protection required, three optional guard designs are available to help protect the cab glass from damage while working in tough forestry applications. There are two front windshield guard options and a full cab glass guarding option available. Protecting the underside of the machine, the power train guard prevents debris build-up and damage to major components or systems such as the engine or transmission.

Configured for Success – Ready to Work for You

Optional Attachments:

- Radiator with Wider Fin Spacing for High Debris Applications

- Engine Precleaner

- Window Guard

- Tilt Cylinder Guard

- Light Guard

- Auxiliary Hydraulics: 3rd and 4th Valve

- Advanced Cabin Filtration

- Power Train Guard

- Variable Pitch Fan

- Counterweight

- Logger Linkage: a. Larger Lift Cylinders; b. Larger Tilt Cylinders

- Fusion Coupler

- LED Lights

- Warning Beacon

- Strobe Lights

- Roading Fenders

- Cat Autolube

- Wheel Chocks

- Axle Oil Coolers (front, rear)

- Traction Aid: Automatic Front/Rear Differential Locks (manual front is standard)

- Low Profile Tires (not shown)

Owning Costs – Proven Best Investment

Customer Support Agreements

A Customer Support Agreement (CSA) is an arrangement between you and your Cat dealer that helps you lower your total cost per ton. CSAs are flexible, allowing them to be tailored to your business needs. They can range from simple Preventive Maintenance Kits to elaborate Total Cost Performance Guarantees. Having a CSA with your Cat dealer enables more time for you to do what you do best – run your business.

Monitoring Systems

Monitoring product health is key to optimizing the life of an investment into a Cat Wheel Loader.

- Cat Product Link – Cat Product Link allows remote monitoring of equipment to improve overall fleet management effectiveness. Product Link is deeply integrated into machine systems. Events and diagnostic codes, as well as hours, fuel, idle time and other detailed information are transmitted to a secure web based application, VisionLink. VisionLink includes powerful tools to convey information to users and dealers, including mapping, working and idle time, fuel level and more.

- S·O·S Services – Helps manage component life and decrease machine downtime, increasing productivity and efficiency. Regular fluid sampling can help track what is going on inside your machine. Wear related problems are predictable and easily repairable. Maintenance can be done to accommodate your schedule, resulting in increased uptime and flexibility in maintenance repairs before failure.

Cat Autolube System

The optional, fully integrated Cat Autolube system provides full system monitoring and diagnostic test visibility by being integrated into the machine, display and VisionLink. Easy access to the refill pump and grease zerks means simple, fast servicing.

Parts Availability

Caterpillar provides an unsurpassed level of personalized service to help you work more cost effectively and efficiently. By utilizing a worldwide parts network Cat dealers help minimize machine downtime and save money by delivering replacement parts within 24 hours.

Resale Value

Owning quality equipment is an important factor in maintaining resale value. Caterpillar is not only known for machines that are better built, but provides product and dealer support to maintain the reliability and durability of your machine.

Operating Costs – Save Time and Money by Working Smart

Customer machine data shows Cat wheel loaders are the most fuel efficient machines in the industry. Several features contribute to this excellent fuel efficiency:

- Deep system integration between engine, hydraulics, transmission and ride control results in reduced emissions, more productivity, and lower fuel consumption without interrupting machine performance.

- Manual/automatic differential locks increase traction and reduce tire scuffing lowering operating costs.

- Productive economy mode optimizes engine torque and speed further reducing fuel consumption.

- External caliper disc parking brake makes maintenance easily accessible.

- Adjustable automatic idle engine shutdown system reduces idle time, overall operating hours and fuel consumption.

- Lock-up clutch torque converter and shift strategy increases driveline efficiency with reduced torque interruption conserving fuel. Auto 1-D transmission mode keeps engine speed low reducing fuel consumption while delivering optimal machine performance.

Customer Support – Unmatched Support Makes the Difference

Renowned Cat Dealer Support

- Your Cat dealer is ready to help you every step of the way. From new or used machine sales, to rental or rebuild options, your Cat dealer can provide an optimal solution to your business needs.

- Unsurpassed worldwide parts availability, trained technicians and customer support agreements maximize your machine uptime.

- Financing options are offered to meet a variety of customer needs.

Serviceable – Easy to Maintain. Easy to Service.

Engine Access

The Cat sloped “one-piece” tilting hood provides industry leading access to the engine. Its design provides the best-in-class service access to engine, oil levels and coolant sight gauge.

Cooling System

The cooling system is readily accessible for clean out and maintenance. With nine cooling fins per 25.4 mm (1.0 in) and a perforated grill, most airborne debris entering the system passes through the cooler cores. The hydraulic and A/C cooler cores swing out providing easy access to both sides for cleaning. An access panel on the left side of the cooling package swings down to provide access to the back side of the engine coolant and Air-to-Air After Cooler (ATAAC). An optional variable pitch fan can automatically purge the cooler cores by periodically reversing the airflow when needed.

Service Centers

The electrical and hydraulic service centers provide grouped access to numerous features, enhancing safety and convenience for your operators and service technicians, while reducing service time.

The electrical service center, located beneath the left platform, contains the maintenance free batteries, a fuse relay panel, main disconnect switch, ground level engine shutdown switch, hood tilt switch, and the jump start receptacle.

Hydraulic system components are protected by full flow and kidney-loop filtration. A filter in the hydraulic tank return line filters all of the oil returning to the tank. There is also a case drain screen for additional protection and finally, a separate kidney-loop filter with a finer micron rating continuously filters smaller particles out of the system. This multilevel design ensures the hydraulic oil is clean and thoroughly protects the rest of the hydraulic system from contamination. A thermal bypass valve has been added to improve hydraulic system warm-up.

The hydraulic service centers are now virtually identical for the M Series product line. This consistent layout makes it easier for service technicians who work on a variety of M Series models.

Стандартное оборудование

-

OPERATOR ENVIRONMENT

- Cab, pressurized and sound suppressed (ROPS/FOPS)

- Viscous mounts

- Multi-function 18 cm (7 in) color touch-screen display for rear vision camera, clock and machine parameters

- EH controls, SAL (single axis lever) lift and tilt function

- Steering, wheel

- Radio ready (entertainment) includes antenna, speakers and converter (12V, 10-amp)

- Air conditioner, heater, and defroster (auto temp and fan)

- EH parking brake

- Beverage holders (2) with storage compartment for cell phone/MP3 player

- Bucket/work tool function lockout

- Coat hook (2)

- Cab air filter

- Ergonomic cab access ladders and handrails

- Horn, electric

- Light, two dome (cab)

- Mirrors, rearview external with integrated spot mirrors

- Post mounted membrane 16 switch keypad

- 2 receptacles, 12V

- Seat, Cat Comfort (cloth) air suspension

- Seat belt, 51 mm (2 in) retractable, with indicator

- Sun visor, front

- Wet-arm wipers/washers front and rear, intermittent front wiper

- Window, sliding (left and right sides)

- Cab tie-off

-

COMPUTERIZED MONITORING SYSTEM

-

With following gauges:

– Speedometer/tachometer

– Digital gear range indicator

– Diesel Exhaust Fluid (DEF) level (Tier 4 Final/Stage IV models)

– Temperature: engine coolant, hydraulic oil, transmission oil

– Fuel level

-

With following warning indicators:

– Regeneration

– Temperature: axle oil, engine intake manifold

– Pressure: engine oil, fuel pressure hi/low, primary steering oil, service brake oil

– Battery voltage hi/low

– Engine air filter restriction

– Hydraulic oil filter restriction

– Hydraulic oil low

– Parking brake

– DEF low level (Tier 4 Final/Stage IV models)

– Transmission filter bypass

-

With following gauges:

-

ELECTRICAL AND LIGHTING

- Batteries (2), maintenance free 1,400 CCA

- Ignition key; start/stop switch

- Starter, electric, heavy duty

- Starting and charging system (24V)

-

Lighting system:

– Four halogen work lights (cab mounted)

– Two halogen roading lights (with signals)

– Two halogen rear vision lights (hood mounted)

- Alarm, back-up

- Alternator, 145-amp brushed

- Main disconnect switch

- Receptacle start (cables not included)

-

CAT CONNECT TECHNOLOGIES

- Link technologies: Product Link

- Detect technologies: rear vision camera

-

POWER TRAIN

- Engine, Cat ACERT meets Tier 4 Final/Stage IV emission standards, or emits equivalent to Tier 3/Stage IIIA

- Cat Clean Emissions Module (CEM) with Diesel Particulate Filter (DPF) and Diesel Exhaust Fluid (DEF) tank and pump (Tier 4 Final/Stage IV models)

- Fuel priming pump (electric)

- Fuel/water separator

- Precleaner, engine air intake

- Economy Mode (selectable)

- Transmission, automatic power shift

- Torque converter, locking clutch with free wheel stator

- Switch, transmission neutralizer lockout

- Axles, manually actuated differential lock front axle, open differential rear axle

- Axles, ecology drains

- Brakes, full hydraulic enclosed wet-disc with Integrated Braking System (IBS)

- Brake wear indicators

- Parking brake, disc and caliper

- Fan, radiator, on demand

-

LINKAGE

- Linkage, Z-bar, cast crosstube/tilt lever

- Kickout, lift and tilt, automatic

-

HYDRAULICS

- Hydraulic system, load sensing

- Steering, load sensing

- Ride control, 2V

- Remote diagnostic pressure taps

- Hoses, Cat XT™

- Oil sampling valves

-

FLUIDS

- Premixed extended life coolant with freeze protection to –34° C (–29° F)

-

OTHER STANDARD EQUIPMENT

- Hood, non-metallic power tilting

- Service centers (electrical and hydraulic)

- Platform, window washing

- Fenders

- Ecology drains for engine, transmission, and hydraulics

- Ether aid ready

- Grill, airborne debris

- Filters: fuel, engine air, engine oil, hydraulic oil, transmission

- Fuel cooler

- Grease zerks

- Hitch, drawbar with pin

- Precleaner rain cap

- Sight gauges: engine coolant, hydraulic oil, and transmission oil level

- Toolbox

- Vandalism protection caplocks

Дополнительное оборудование

-

OPERATOR ENVIRONMENT

- Door, remote opening system

- Cover, HVAC metallic

-

EH controls, SAL 3rd function

– Additional roller switch for 4th function

-

EH controls, joystick lift and tilt

– Additional integrated roller switches for 3rd and 4th functions

- EH joystick

- Filter, carbon fresh air

- Mirrors, heated rearview external with integrated spot mirrors

- Precleaner, HVAC

- Precleaner, HVAC (RESPA)

- Radio, AM/FM/USB/MP3 Bluetooth®

- Radio, AM/FM/CD/USB/MP3 Bluetooth

- Radio, AM/FM/CD/USB/MP3 Bluetooth with Satellite Sirius and XM

- Radio, CB ready

- Seat, heated air suspension

- Seat belt, 76 mm (3 in) retractable, with indicator

-

Steering, EH wheel with directional FNR shifter and gear selector

– Additional FNR with implement controls

- Roof, metallic

- Steering, secondary

- Sun visor, rear

- Windows, rubber mounted

- Windows, with front guard

- Windows, with heavy duty front guard

- Windows, with full guards front, rear and sides

-

ELECTRICAL AND LIGHTING

- Four additional auxiliary halogen cab mounted work lights or

- Two additional auxiliary front HI LED and two additional auxiliary rear LED cab mounted work lights with 2 LED work lights in the radiator grill and LED front turn signals also includes replacement of the standard four halogen cab mounted work lights with four LED work lights (standard offering and only roading light available is the halogen roading light)

- Warning amber strobe beacon

- Reversing strobes

- External seat belt indicator light

- Speed limiter – 20 km/h (Europe only)

-

STARTERS, BATTERIES, AND ALTERNATORS

- Cold start – 120V

- Cold start – 240V

-

CAT CONNECT TECHNOLOGIES

- Link technologies: VIMS™

-

Payload technologies:

– Advanced Productivity subscription

– Cat Production Measurement 2.0

– Printer

– Aggregate Autodig

-

Detect technologies:

– Cat Rear Object Detection

- Machine Security System

-

POWER TRAIN

-

Axles

– Automatic front/rear differential locks

– Axle oil cooler

– Extreme temperature seals

– Seal guards

- Fan, VPF (variable pitch fan), automatic and manual control

- Radiator, high debris with wider fin spacing

-

Axles

-

WORK TOOLS

- Fusion quick coupler

- Performance Series buckets

- Millyard forks

- Grapple forks

- Logging forks

- Log and lumber forks

- Pallet forks

- Millyard pole forks

- Woodchip buckets

- High dump buckets

-

HYDRAULICS

- 3rd function with Ride Control

- 4th function with Ride Control

-

FLUIDS

- Premixed extended life coolant with freeze protection to –50° C (–58° F)

-

OTHER OPTIONAL EQUIPMENT

- Cat Autolube System

- Fenders, roading

- Guard, power train

- Oil change, high speed engine

- Precleaner, turbine

- Precleaner, trash

- Wheel chocks

- Low profile tires

- Auto idle shutdown